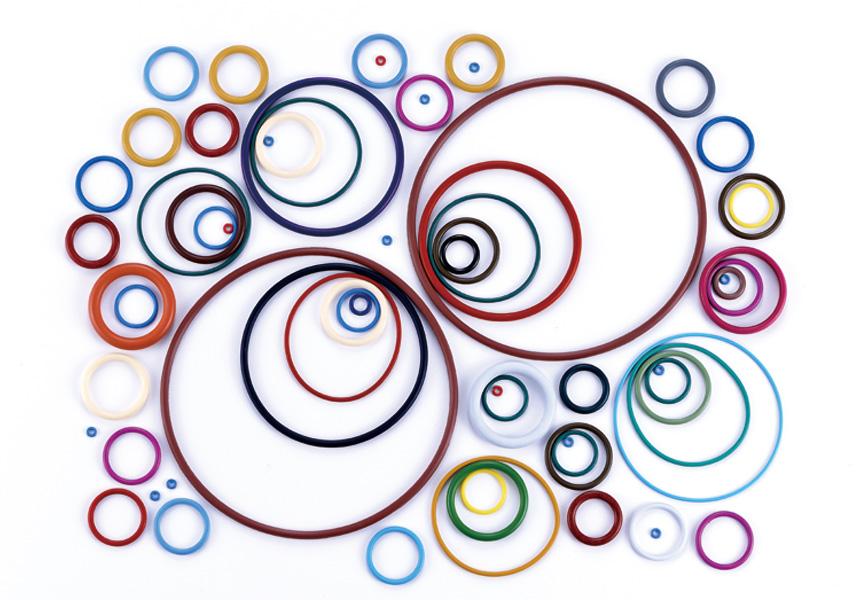

O-RING

In addition to complementing gaskets and other sealing devices, O-rings and seals are critically used in all kinds of applications and may even be customized to fit your engineered gland. Typically designed to seal against all kinds of situations, such as temperature variations, cryogenic conditions and chemical leaks. Our O-rings come in all the standard sizes available, and Essons also offers a wide range of elastomeric materials to better suit your specific needs.

OIL SEALS

Oil seals are devices used to seal oil inside a machine or piece of equipment. These seals make use of lubricants to prevent water, chemical compounds, gases or other materials from leaking out of machinery, and simultaneously prevent the intrusion of dust, sand or other foreign objects from outside the world.

RUBBER DIAPHRAGMS

Rubber and fabric-reinforced rubber diaphragms are critical to the operation of equipment and systems in the industrial, automotive, aerospace, oil, gas, medical instrumentation, and pump and valve industries. Diaphragms reinforced with fabric are typically used for regulating and controlling the transmission of force, such as linear actuators and drives. If a dependable and accurate response to a hydraulic or pneumatic pressure change is needed then a diaphragm seal is most likely required.

Esson’s technology and expertise with diaphragms means that we fully guarantee to meet our customer’s needs successfully.

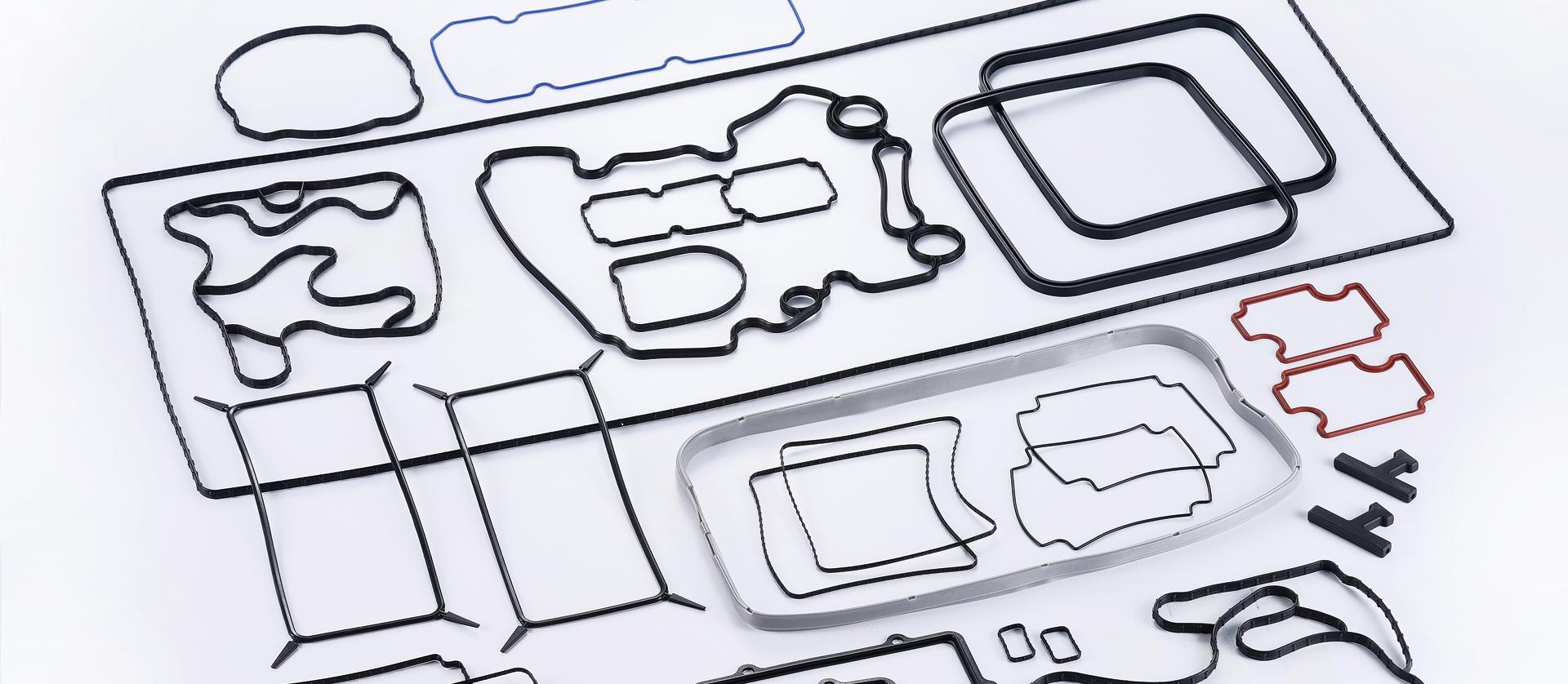

ELASTOMER/ FLAT METAL GASKET

A gasket is a mechanical seal that fills the space between two objects, generally to prevent leakage between the objects while under compression. Gaskets save money by allowing less precise mating surfaces on machine parts which can use a gasket to fill irregularities. With Esson’s advanced technology we provide parts that are perfectly fitted in any irregular parts in any required condition.

CUSTOM MOLDED RUBBER PARTS

With engineering expertise and 40 years of tool development of experience Essons provide engineering support and quick response on development and design to satisfy your requirements. With a wide range of materials and vast experience in material development, Essons can ensure that your parts will perform in any type of critical condition.

Custom seals, molded rubber or rubber bonded to metal/plastic parts manufactured by ESSONS meet or exceed most specifications. Whether you need a prototype run or high/low volume production, we offer single or multi-cavity tooling with competitive tooling costs. ESSONS has the capability to manufacture custom seals for any application while providing the most efficient and cost-effective solutions.

■ Speedy response on prototype.

■ Engineering advice and support on your design requirements.

■ Lists of material and material experience ensure your part’s performance.

■ Quick turnaround to meet your due dates.

■ In house tooling manufacturing.

■ Rubber Injection Molding / Compression Molding / Transfer Injection Molding.

■ Custom molded size cover from 0.50mm to 1500mm.

■ IATF16949, ISO 9001 & ISO 14000 approved.

■ Prototypes through production quantities.

■ Continuous cost control.

■ Rubber material available for a wide range of temperatures, aging conditions and all kind of chemical resistant.

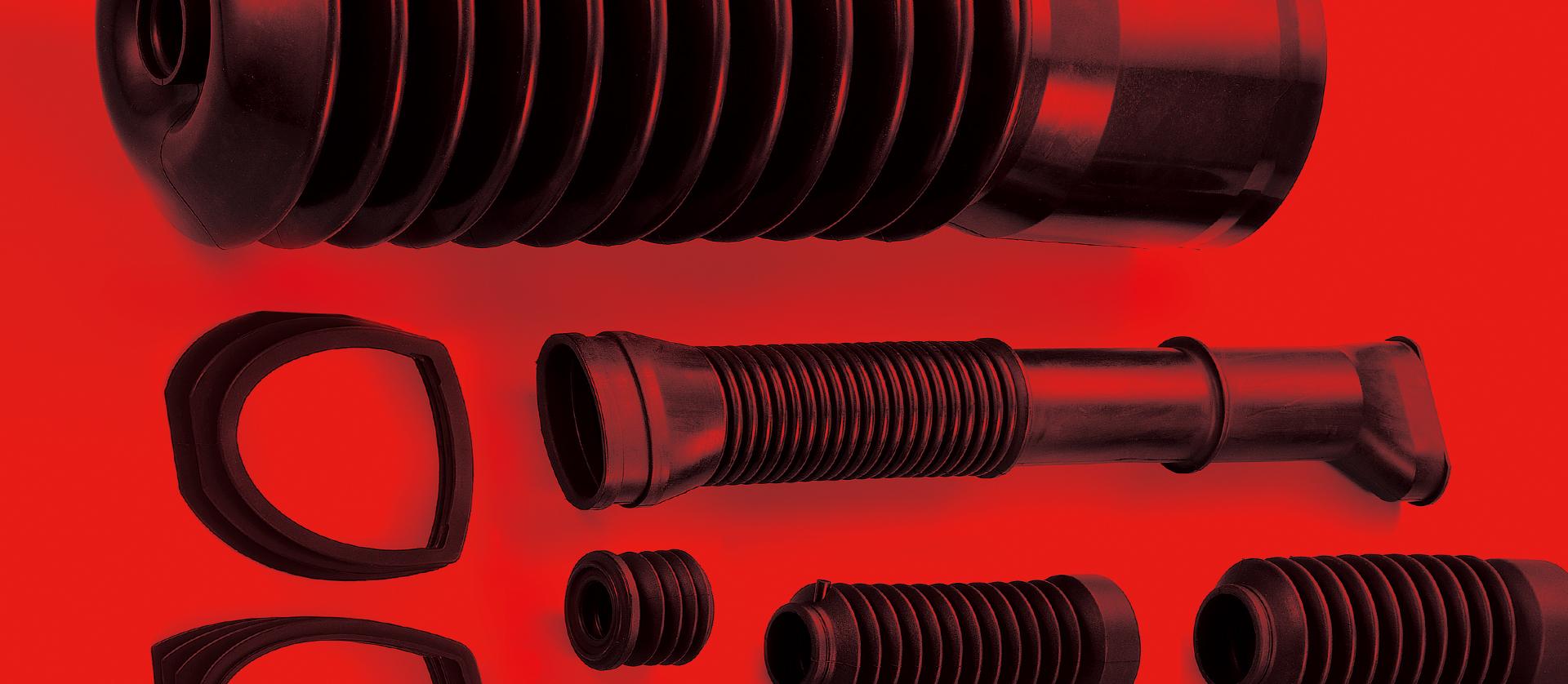

BOOTS & BELLOWS

Whether you need to protect from dust, moisture, oils, chemicals or any other environmental element, such as UVs, Essons is able to offer custom solutions based on your specific requirements. Whether it is bellows, boots or covers, we provide a range of flexible and versatile products while even suggesting the best suited material for your application.